Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

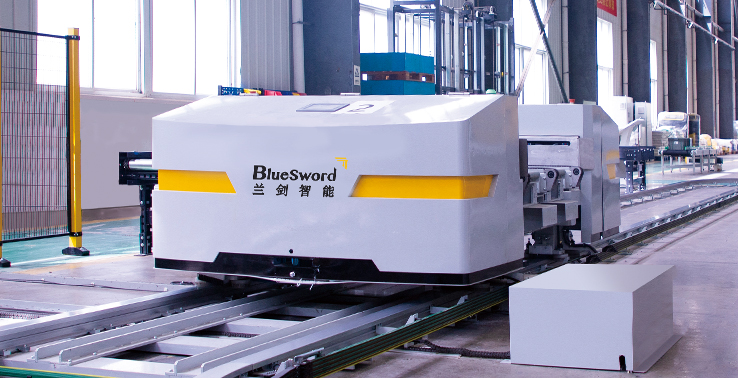

It has a R&D team led by a number of doctors and masters, ranking among the best in the same industry in China. After nearly 30 years of development, the company has established an excellent R&D team integrating mechanical design, electrical design, PLC control, electronic design, software control, artificial intelligence, big data, business intelligence and other professionals.

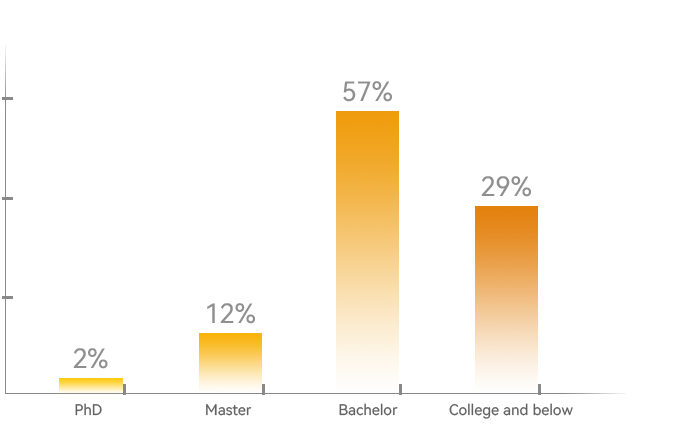

The R&D team has a high level of education, with nearly 70% of the team having bachelor's degree or above, several doctors have studied in Georgia Institute of Technology ISyE. We have established a national logistics engineering talent training and practical training base, and creatively implemented a comprehensive orientation training program for logistics engineering talents.

43%

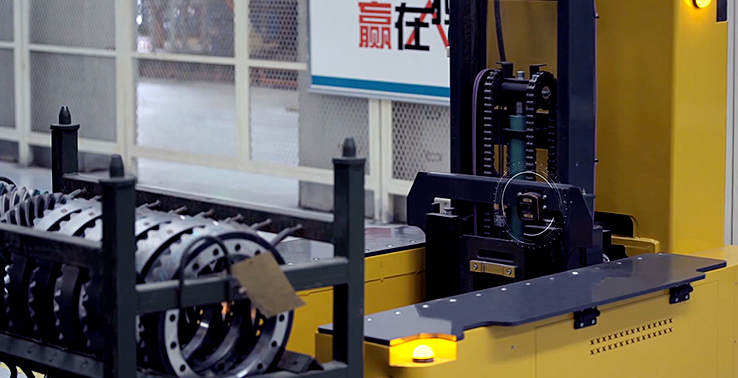

Production

8%

Sales

28%

Technical

21%

Others

Fast Sorting Theory

Active Storage Theory

A System of Kongming Optimization Algorithm

Original Logistics Theoretical System

Original Logistics Theoretical System

Fast Sorting Theory

Active Storage Theory

A System of Kongming Optimization Algorithm

More comprehensive mechanical analysis and more reliable structure.

Keeps equipment running fast and steady.

Judging abnormal conditions in advance, avoiding the risk of accidents, and operating smarter and more stable.

Reduce the probability of traffic control and increase the efficiency of parallel work of large-scale AGVs.

Layering and grouping work in parallel for more efficient depalletization.

Seamlessly adjust the distance between two fork plates to access different size cases.

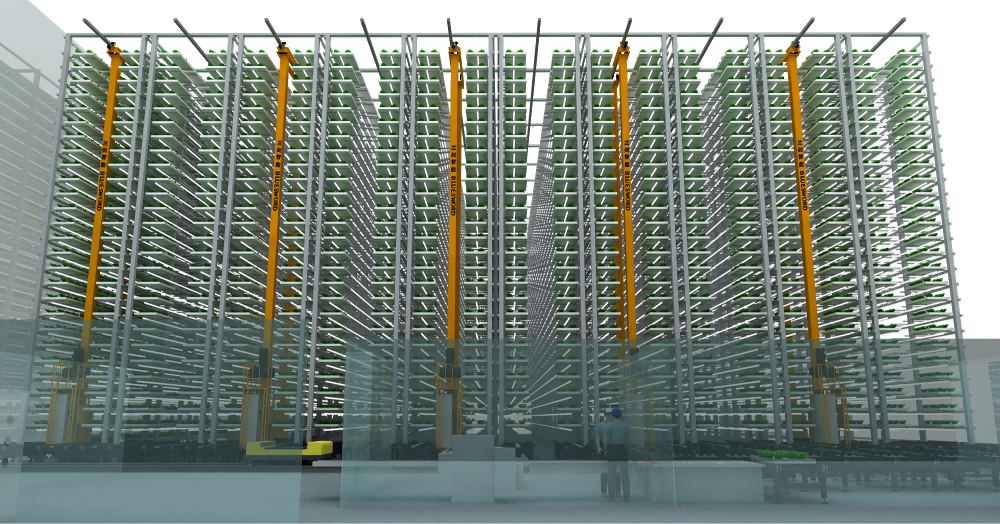

More than 10% higher seismic performance than common shelf structure in the industry.

Shelf storage density can be increased by more than 30% .

Pre-sorting of all brands of cigarettes to improve the efficiency of cigarette picking.

Recyclable to improve the loading rate of distribution vehicles and simple recycling operation.

More than 10% increase in equipment work parallelism over random inbound scheduling technology.

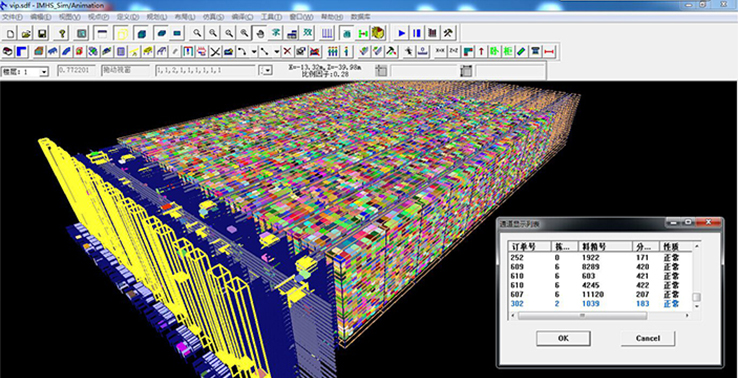

Real-time dynamic online simulation to meet the diverse simulation needs of logistics automation systems.

BlueSword has undertaken the major special project of Shandong Provincial Science and Technology Department "research and application of key technologies of intelligent logistics robots"; It has won a number of awards and honors from government departments such as the "new generation of AI industry innovation key task winner" of the Ministry of industry and information technology of the people's Republic of China, and the "first batch of Jinan manufacturing single champion enterprises" of the Jinan Bureau of industry and Information.

The company has established BlueSword Research Institute, which is mainly responsible for researching the current situation and future development trend of the industry in which the company is located, guiding the direction of the company's R&D, and coordinating the division of labor and cooperation among various R&D departments in the project R&D.

Mr. Wu Yaohua, Doctor of Engineering of Tsinghua University, Doctoral Supervisor of Shandong University and Chairman of BlueSword Intelligence, is a technical expert who has been engaged in the warehouse logistics automation industry for more than 30 years, not only has a deep theoretical foundation, but also has accumulated rich technical practical experience in his work.

Intelligent Agriculture

BlueSword Intelligence combines years of accumulated experience in plant-based intelligent manufacturing technology with the characteristics of intelligent agricultural equipment, applies the results of advanced industrial automation manufacturing technology to the creation of plant technology and equipment, and successfully develops complete sets of plant automation technology and equipment through the research of key technologies such as machine vision recognition judgment and artificial intelligence.

BlueSword intelligent automated plant factory mainly consists of the following systems: automated seed sowing machine, seedling sub-planting robot, harvesting robot and automated logistics control system; intelligent LED precision dimming system; high cultivation volume workshop uniform environment control system, nutrient solution real-time monitoring and disinfection system, plant growth online monitoring diagnosis and control system; leafy vegetable production intelligent monitoring and autonomous intelligent management system, etc.

Fill out your information, BlueSword will provide you professional service!