Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Jun 23 /2021

share to

As a full-process intelligent logistics system solution provider, BlueSword is committed to providing customers with expert-level consultative sales and creating customized high-end applications. Today, I will share with you the Lanjian ring RGV system solution.

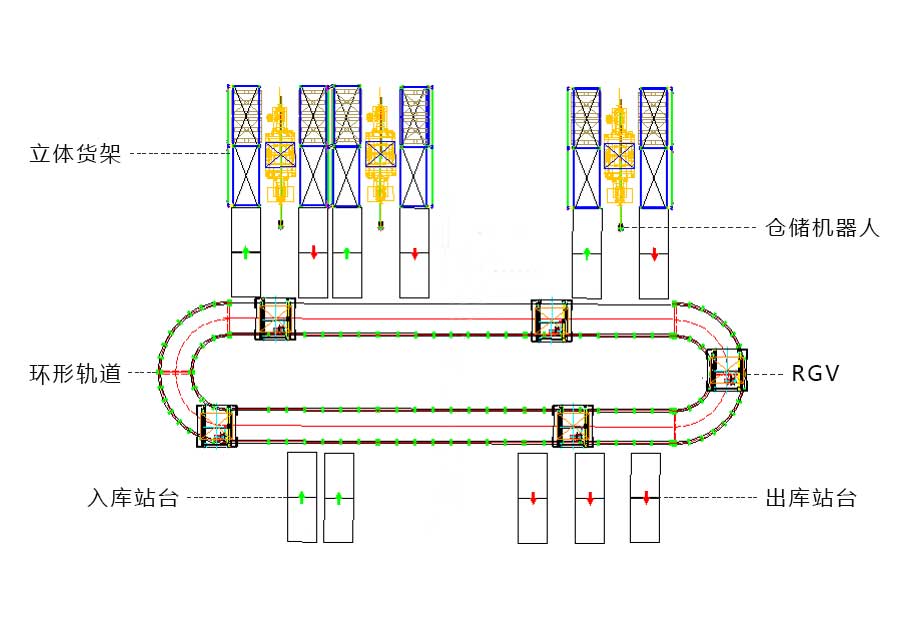

Rail Guide Vehicle (RGV) is widely used in automated warehousing and logistics systems. It is the link between storage shelves and handling systems.

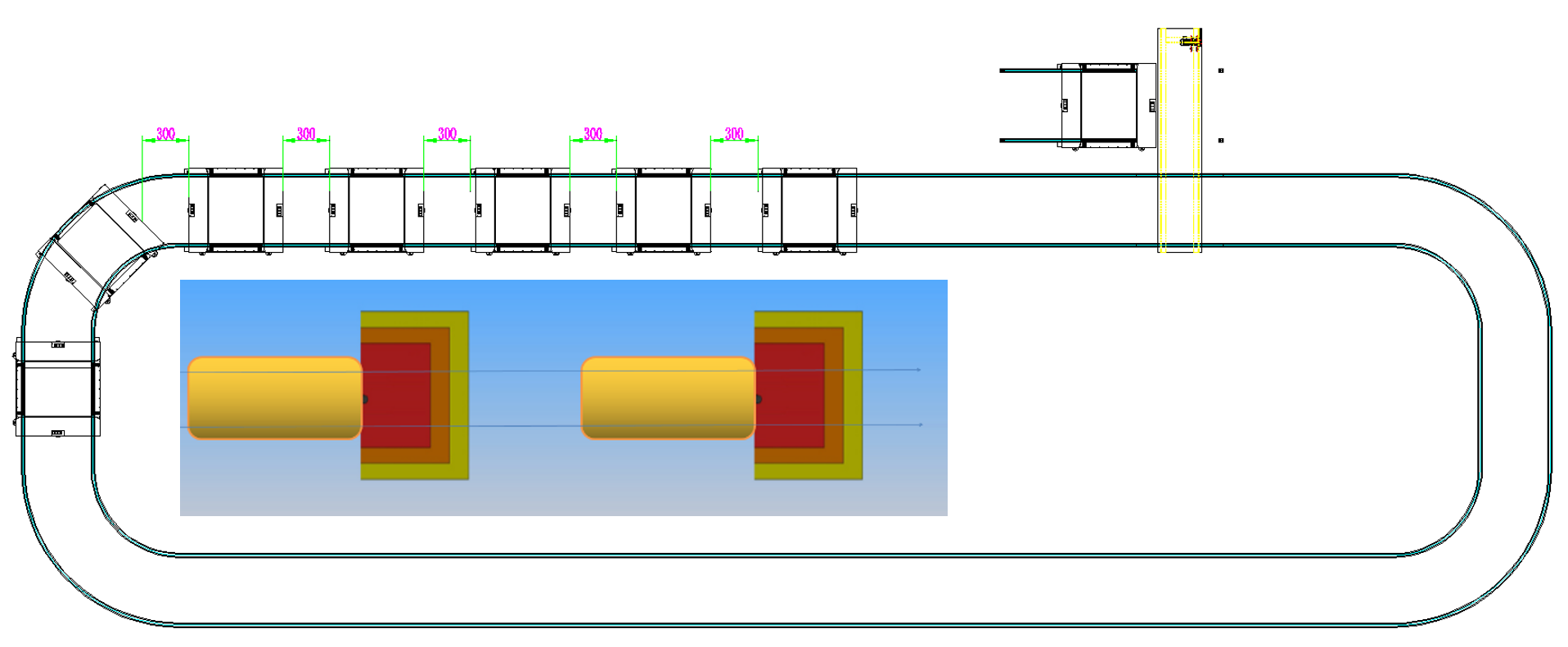

The traditional RGV mostly uses the linear reciprocating transportation mode, which is characterized by simple system and low cost, but limited transportation capacity; in order to meet the larger-scale in-out and outbound requirements of AS/RS, the circular RGV is developed on the basis of the linear reciprocating RGV. Therefore, the track is arranged in a closed loop in the plane, which can operate multiple RGVs at the same time, greatly improving the handling capacity and handling efficiency, which is the development trend of RGVs in the future.

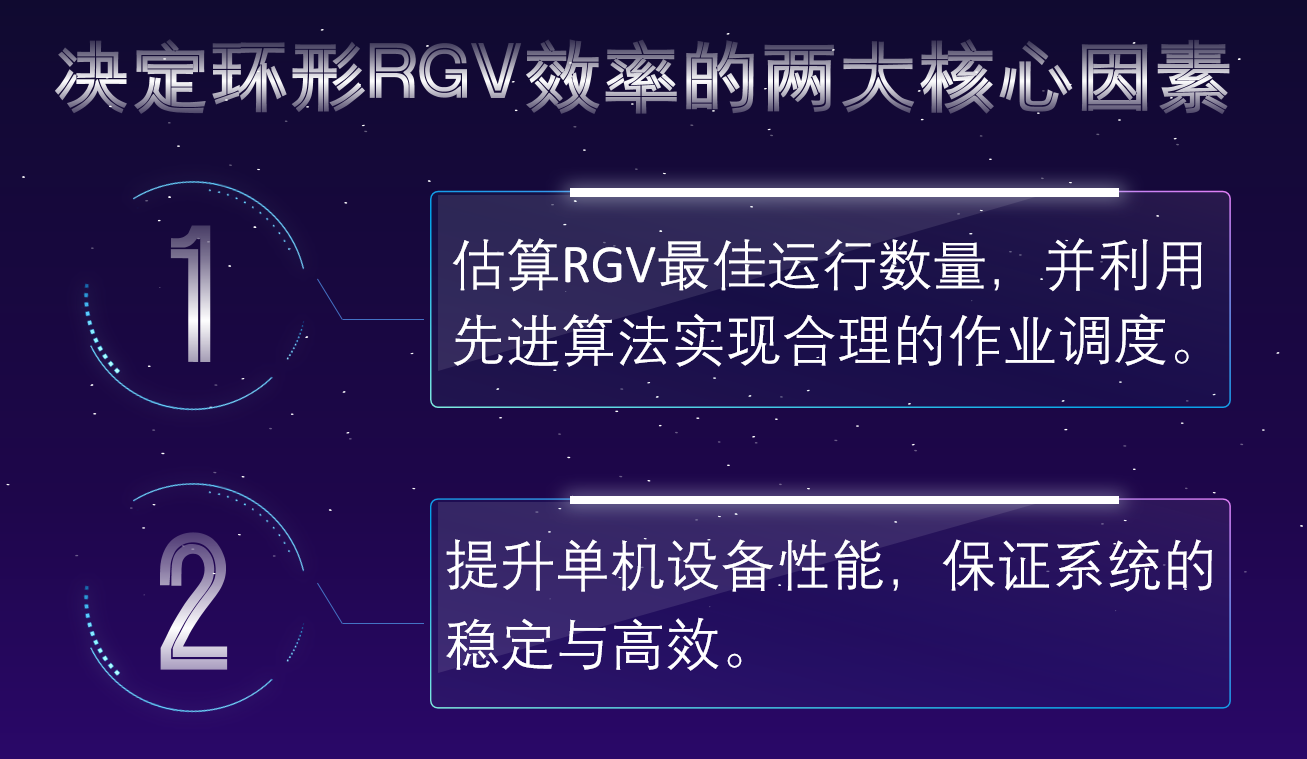

Starting from the real needs of the market, BlueSword comprehensively considers the two decisive factors of the overall collaborative scheduling of the RGV system and the capability of the RGV stand-alone equipment, and designs a more intelligent, more efficient and more applicable ring RGV system solution.

1. Optimal scheduling of multiple trains on the ring track

In the multi-vehicle mode of the ring-track, the RGV travels in one direction, and drives to the target platform to pick up the goods in sequence according to the received task information. The RGV traveled along the track for a week, and after picking up the goods once, went to the platform to accept a new task.

The number of RGVs directly affects the outbound efficiency and overall capacity of the system: too few RGVs will cause a backlog of goods on the platform, affecting the outbound capacity; if too many RGVs, the equipment utilization rate will not be high, and it will easily cause blockage after occupying the track. It will also affect the overall efficiency of the system. Therefore, reasonable estimation of the number of RGVs and optimal scheduling are the core issues of the annular RGV system.

How does Lanjian Intelligence face this problem to ensure the optimal system capability?

· Provide customized services for real needs

When providing customers with a local annular RGV system,BlueSword provides not only a set of equipment, but also a full-process customized service that can solve real needs.

Before the system construction for the customer, BlueSword will comprehensively grasp the customer's business situation through on-site research, data analysis and other means. On the basis of comprehensively considering the existing business needs and future business expansion, the expert team will carry out the applicability plan. design.

The most suitable is the best, which is the planning principle of BlueSword. This principle is more vividly reflected in the design of the annular RGV system. There are not many cars, and efficiency is the basis. Through reasonable planning, using a smaller number of RGVs to complete more in-out and out-of-warehouse tasks is the embodiment of the handling capacity and the customer's appeal.

· Algorithm optimal principle to realize intelligent scheduling

The scheduling of the RGV determines the execution of the system handling operations. The number of vehicles is reasonably planned but the scheduling is poor, and it cannot meet the efficiency requirements.

BlueSword comprehensively analyzes the impact of waiting, starting and stopping, compound operations, etc. on the handling efficiency when RGV performs handling operations, and establishes a genetic algorithm and queuing theory. Optimal scheduling algorithm for circular RGV handling operations based on theory.

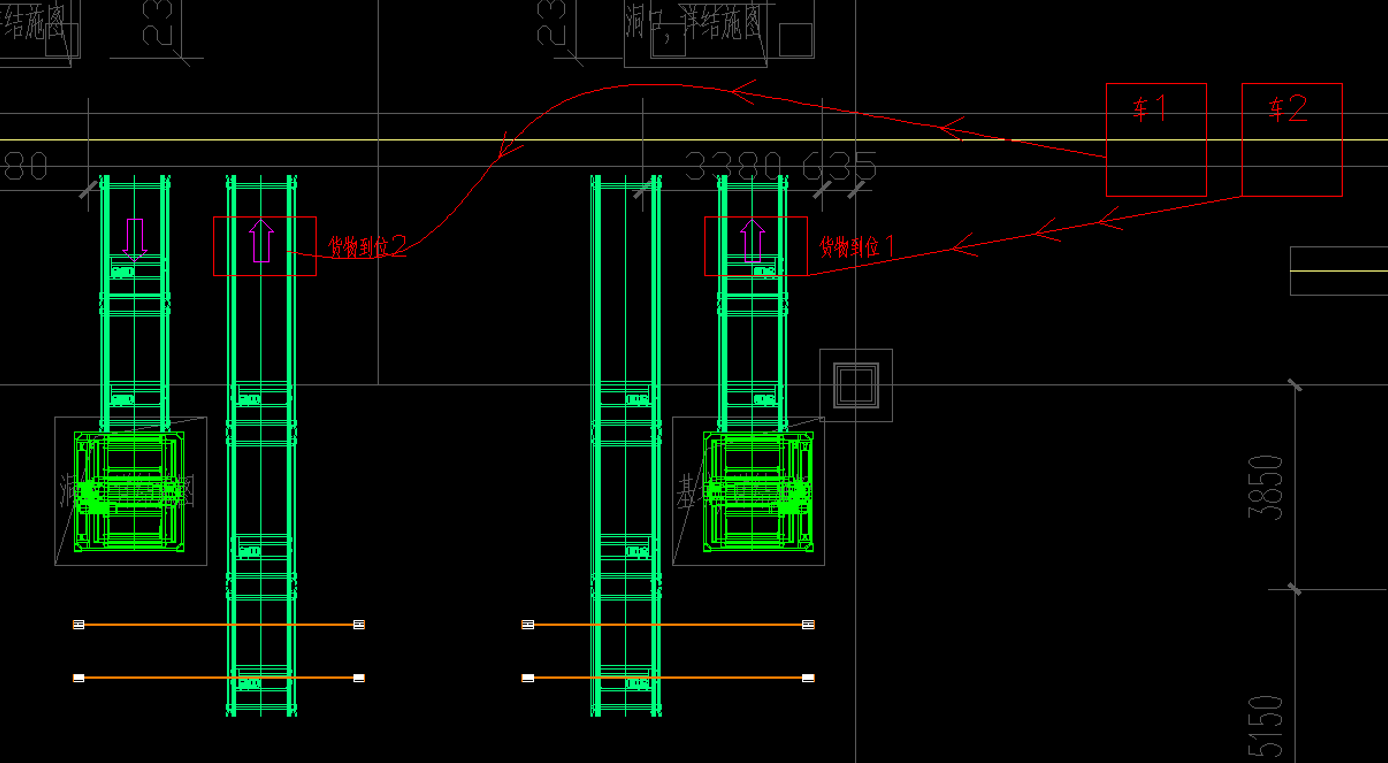

Different from ordinary scheduling algorithms, Lanjian's intelligent annular RGV system adopts the optimal principle of snake tail, that is, when cargo 1 and cargo 2 are in place and car 1 and car 2 arrive at the same time, car 1 can directly pick up cargo 2, Car 2 picks up cargo 1. Compared with the conventional practice - Car 1 must pick up Cargo 1, Car 2 must wait behind, then move forward together, and Car 2 will pick up Cargo 2, which can save the vehicle waiting, start-stop time, not only the system efficiency is significantly improved, but also the equipment Loss is also greatly reduced.

Figure: Common Scheduling Algorithm

Figure: Snake tail optimal principle

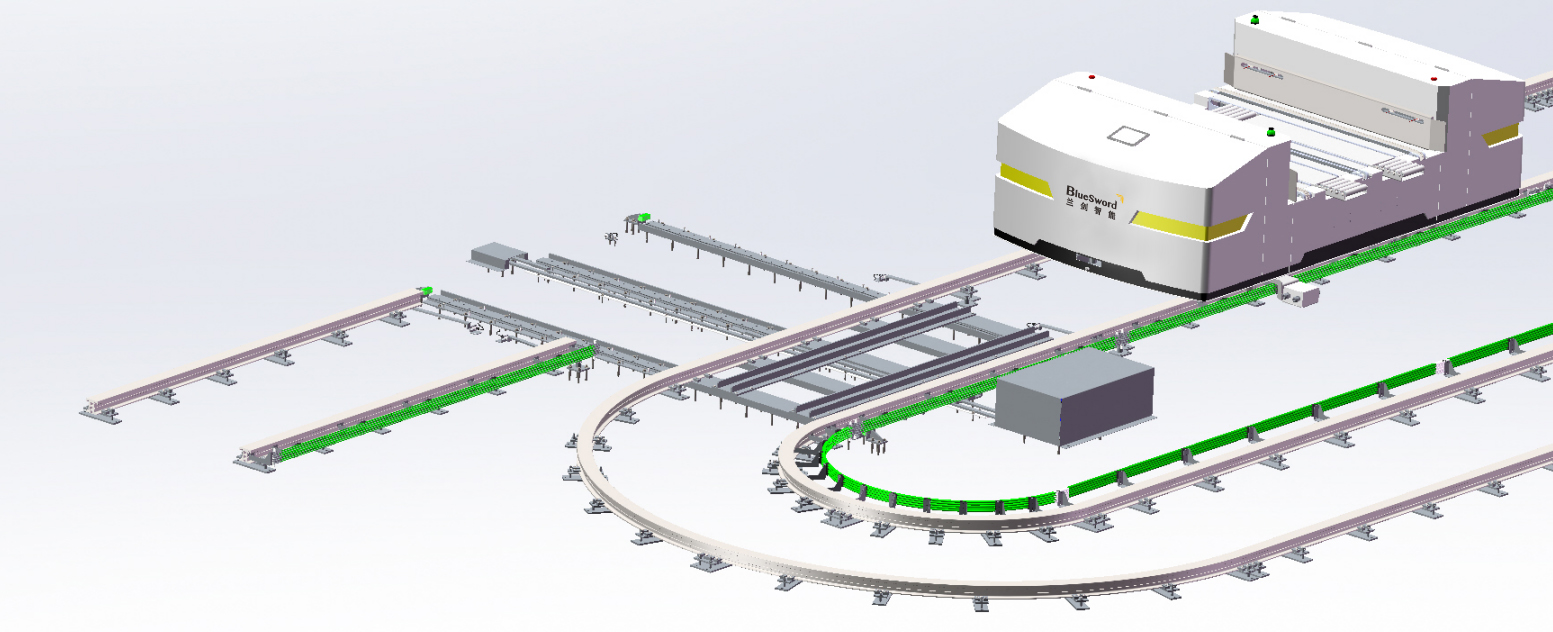

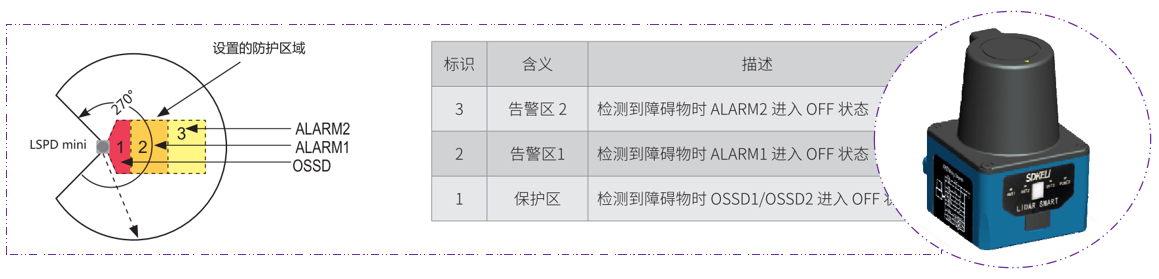

Vehicle-following control is also a very important part of the scheduling process. Lanjian intelligent circular RGV system is based on the safety obstacle avoidance strategy of lidar multi-level area scanning and Autopilot technology to achieve precise ranging function, and adjust the speed of front and rear vehicles in real time according to the distance, Acceleration to achieve constant-distance cruise following the vehicle, and the following distance can be set according to different warehouse requirements.

Under the powerful following control function, the two-vehicle linkage and automatic following can also be realized in the turning link. When the vehicle in front turns, the vehicle behind does not need to wait absolutely still, and the two vehicles can turn at a constant speed at the same time.

· Simulation and verification to maximize customer benefits

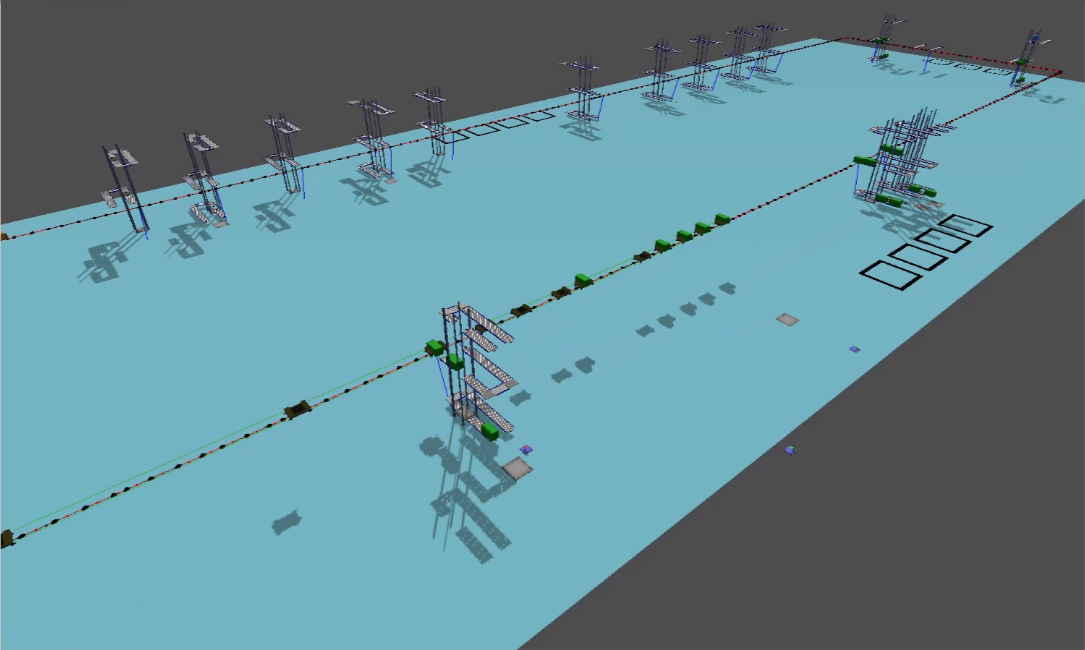

Simulation software is also an advanced weapon for system optimization. Lanjian Intelligent applies the self-developed 3D logistics simulation software to transform the planning scheme into a business entity model, with 1:1 high-precision proportional modeling. Import the real data such as inbound and outbound storage, run the simulation continuously on the software and output the simulation report, find out the efficiency bottleneck of the scheme and the deadlock point of the logistics link to effectively optimize.

Simulation verification can ensure the scientificity and reliability of the system, reduce the number of changes and rework of the physical system in the subsequent production execution links, and maximize customer benefits.

2. Excellent performance of stand-alone equipment

The high performance of the RGV stand-alone equipment is the basis for ensuring the stability and efficiency of the overall system. BlueSword's RGV products have unique advantages in walking, communication, maintenance, and safety.

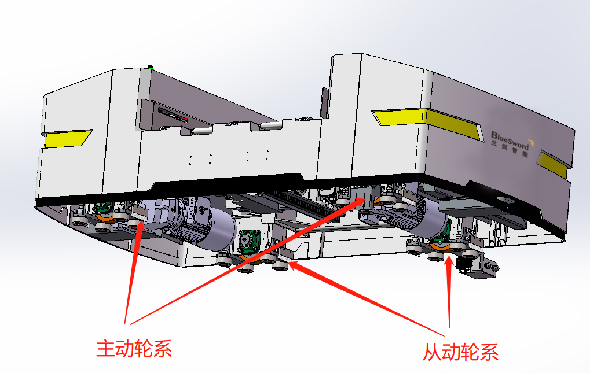

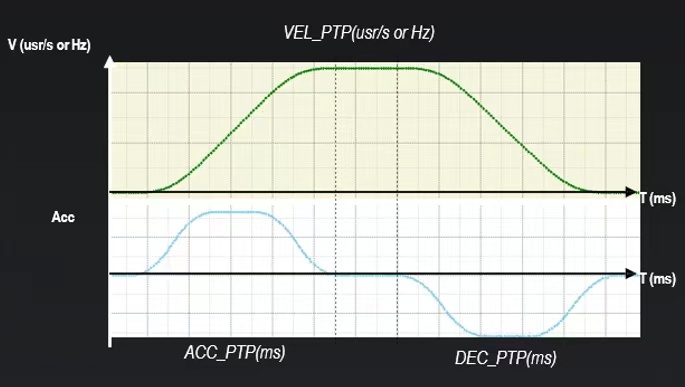

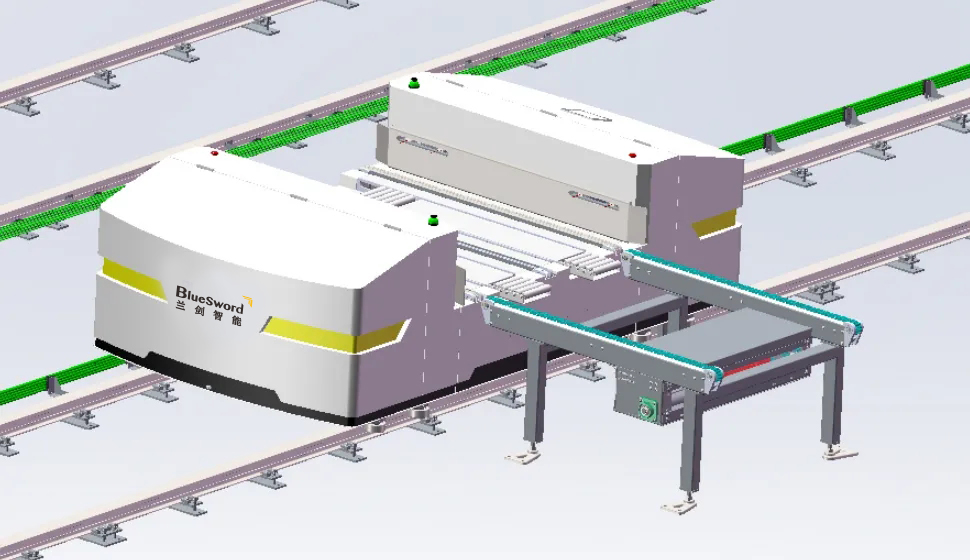

· Dual-drive + S-curve design, higher speed and stability

Adopting the dual-drive design and S-curve design of active gear train + driven gear train not only enables the car to obtain faster speed and acceleration, but also balances the force on the car body, so that the car body can maintain higher stability when walking at high speed. .

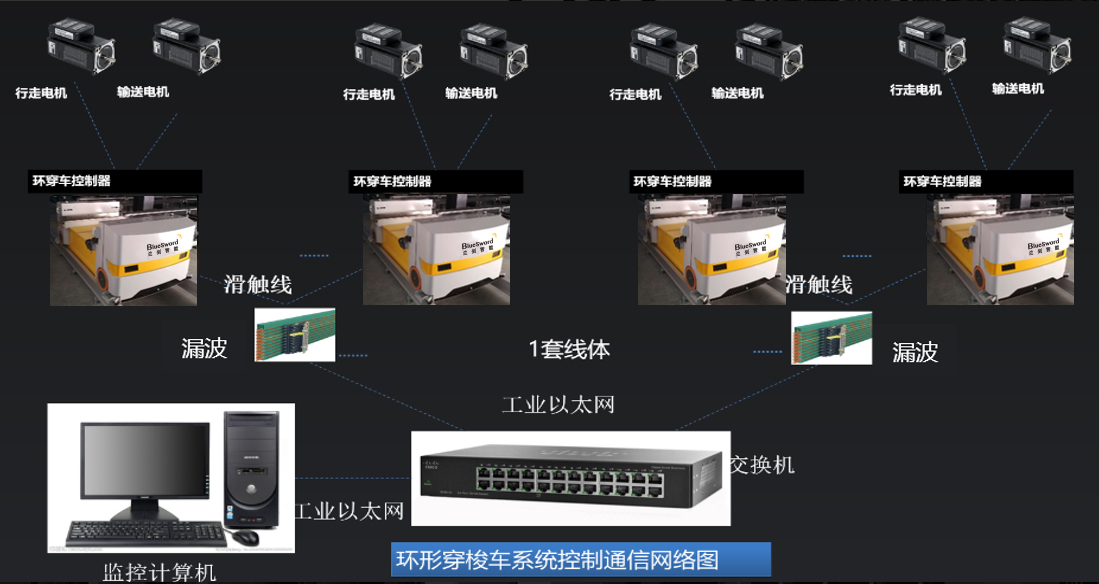

· Leaky wave cable communication to prevent "data packet loss"

There are generally two communication methods - wireless AP and leaky wave cable communication, which can be selected according to different scenarios.

Wireless AP is suitable for small loop lines within a range of tens of meters, but it has a fatal defect that cannot be repaired - "data packet loss"; large loop lines of several hundred meters mostly use leaky wave cable communication, which can solve the problem of packet loss.

· Remote control of faulty vehicles, saving time and effort

The conventional method of handling faulty vehicles is to manually push the faulty vehicle to the maintenance station. The weight of a single vehicle + cargo is about 2 tons, which is very labor-intensive and material-intensive. Lanjian's intelligent system can realize remote control of faulty vehicles (except those with damaged wheels) into the maintenance section, saving people and time and effort.

· Lidar obstacle avoidance to ensure the safety of people and vehicles

Using lidar obstacle avoidance sensor, the obstacle avoidance zone is a 270° sector surface, and multiple zone groups of different shapes can be set through software. It can not only ensure that measures are taken in time when obstacles appear within the range, but also minimize the following distance and improve operating efficiency.

BlueSword focuses on the high-end market and leading enterprises, and designs a highly intelligent and customized ring RGV system solution, which has important practical significance for improving the efficiency of the entire automated warehousing and logistics system.

Fill out your information, BlueSword will provide you professional service!