Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Aug 24 /2021

share to

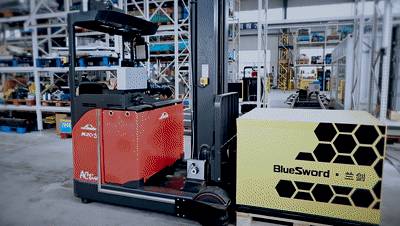

At present, ordinary AGV products on the market have basically met the unmanned storage needs of flat and mid-level warehouses, but in the field of high-level unmanned storage, products are relatively scarce due to the high technical threshold. [Intelligent Manufacturing Impossible] The fifth phase explores the infinite potential of Lanjian intelligent high-position reach forklift AGV.

On the basis of the technology of the original AGV series, BlueSword has carefully developed a high-level front rack integrating the functions of walking, steering, fork lifting, gantry forward movement, recovery, fork side shifting, forward tilting and backward tilting for high-level shelf access. Mobile forklift AGV.

high

The maximum lifting height is 11.45 meters

Benefiting from a smaller footprint and larger storage capacity, high-level shelves have become an increasingly common type of shelf in warehouses, and the complexity and difficulty of goods access also increase significantly with the increase in shelf height. At the same time, higher requirements are placed on the technical level of forklift drivers. Enterprises may face the problem of excessive labor costs, or directly fall into the difficulty of recruiting.

This AGV of BlueSword can pick up and place pallet goods up to 11.45 meters, and can independently complete a series of warehousing and unmanned operations such as warehousing, shelving, shifting, picking, and inventory. It not only saves labor costs for enterprises, but also significantly improves the accuracy of cargo access and the safety of warehouse operations.

In addition, high-level AGV is also an artifact that can rejuvenate old warehouses. The cost of demolishing and rebuilding the old warehouse is too high and the cycle is too long. This product can realize a plug-and-play unmanned upgrade without changing the existing shelf layout.

comprehensive

Suitable for -20℃ low temperature, full scene operation

The operating temperature of many AGV products on the market today needs to be above 0°C. When running in a cold storage, there will be problems such as failure of core components, difficulty in battery life, inability to charge, and obstacle avoidance functions due to water or ice on the ground.

BlueSword Smart AGV overcomes low temperature barriers through technological innovation, has stronger adaptability to temperature, and can still operate efficiently and stably in -20°C cold storage. For food, medicine and other cold storage, it is the best choice for intelligent upgrade.

In practical applications, there are also situations in which AGVs need to shuttle frequently between the normal temperature area and the cold storage area. As a result, the water vapor in the air will condense on the sensors such as the AGV body and lens, which is also a big problem that affects the performance and life of the AGV.

This AGV of BlueSword takes reasonable measures to ensure that no condensation occurs; to ensure that water splashing on the surface does not affect the circuit; to ensure that the anti-corrosion treatment is in place effectively. It can shuttle freely between the normal temperature area and the cold storage area, and complete the efficient handling operation of the whole scene.

intelligent

Detection, scheduling, monitoring, early warning

There are two key points in the field of high-level unmanned storage—narrow aisle operation and high-precision detection, which are also technical difficulties that many manufacturers cannot overcome.

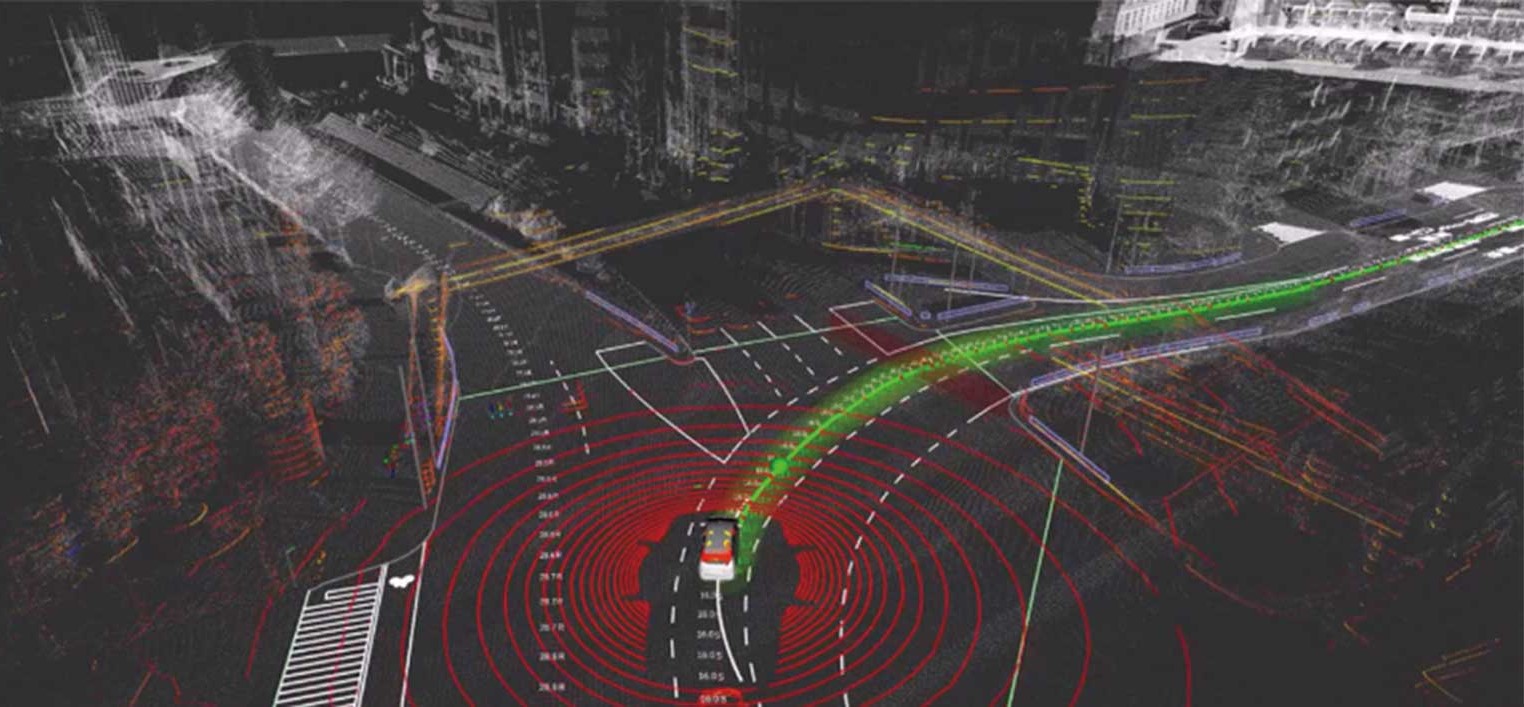

This AGV of BlueSword can not only realize the pick-and-place and automatic loading of narrow aisle space, but also apply intelligent vision system and high-precision pattern recognition algorithm, which can accurately detect the situation of cargo space, shelf shaking, pallet fork hole position and deviation. According to the real-time status, it can perform automatic deviation correction, adaptive motion control and avoid obstacles to prevent collision, dragging and other phenomena, so as to ensure the efficient, accurate and safe cargo handling.

At the same time, the monitoring system can remotely display the operation of each AGV in real time and in full dynamic. Through database storage and big data analysis, it can proactively warn whether equipment or key components need maintenance and overhaul to ensure the overall stable operation.

The high-position reach forklift AGV is another masterpiece of BlueSword's "Worry before customers, and travel before the market". With the increasingly wide range of landing applications, its customer value in the field of high-level unmanned storage has become more and more prominent, and it has unlimited development potential!

Fill out your information, BlueSword will provide you professional service!