Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Feb 18 /2016

share to

What does one ant remind you of? How about a group of ants? I believe we have all seen the scene of a group of small ants carrying food several times their size, and we don't think too much about it after marveling at their natural strength. But BlueSword has creatively developed a distributed automated logistics system along the lines of "Ant Soldier", which is suitable for e-commerce warehousing and logistics and can realize storage and distribution as one - "Honeycomb E-Commerce 4.0 System ".

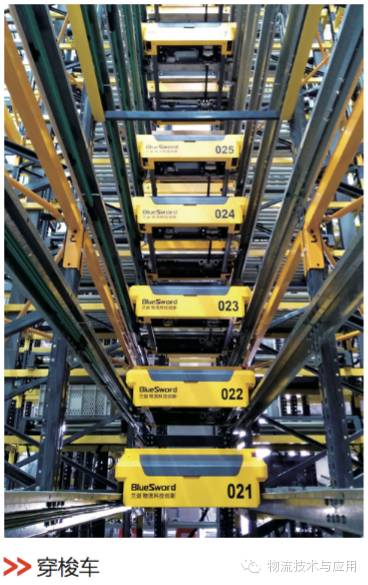

On December 13, 2015, this system, which took just over four months to build, was officially launched in Vipshop's South China logistics center and held a press conference for the public. A milestone." Upon entering the launch site, the scene in front of us caught the reporter's eye: a small, agile and bright-looking yellow lane shuttle car "embracing" blue crates, running like a bee on the shelf track, under the command of the central dispatching system, the shuttle car carried crates with three big letters VIP. Faced with this scene, the hundred experts in the field of e-commerce logistics present were deeply attracted.

What is the "Honeycomb 4.0 System"?

What exactly is this system? What is the "superiority"?

This also has to start from the "ant soldier". "The ant in nature is actually a very smart creature, good at breaking down a complex task into small tasks, and the tasks are completed by multiple ant handovers. Although small in size, ants are able to play the advantage of 'group army combat'." Dr. Wu Yaohua, Chairman of BlueSword Logistics Technology, explained that it is along this line of thought that BlueSword overturned the current traditional centralized automated logistics system and innovatively used the architecture of "distributed automated logistics system" to build an agile logistics system that integrates warehousing and sorting functions, and Hive E-Commerce 4.0 was born.

According to Dr. Liu Peng, General Manager of BlueSword E-Commerce Business Group, the Honeycomb E-Commerce 4.0 system is mainly composed of three intelligent movement units and intelligent picking stations, namely, intelligent lane shuttle, ultra-high-speed transfer shuttle and high-speed vertical elevator. The system is driven by BlueSword's Pro-XTM series software and Bee-NetTM series large-scale scheduling algorithm and calculation engine to realize the precise cooperation of hundreds of intelligent motion units and complete the "goods-to-person" picking of orders with high speed and accuracy.

It is reported that this "goods-to-person" system has comprehensively surpassed the flat "goods-to-person" system currently used by Amazon in terms of principle, composition, function and performance, and has outstanding advantages in several aspects: firstly, the system effectively utilizes the warehouse height space, saving area and increasing the volume rate manifold. Secondly, the system eliminates the need for pickers to walk around a lot and find the goods, resulting in several times the processing efficiency of traditional systems; in addition, the system significantly reduces the number of operators, significantly improves picking accuracy, and further improves safety. The system is designed to be flexible and modular, so that the number of modules or modules can be configured according to the user's order picking volume, allowing for efficient and applicable order picking.

Why did you develop the Honeycomb 4.0 system?

Based on the extraordinary performance of the Honeycomb 4.0 system, it is considered "a revolutionary innovation to traditional warehousing and logistics! . Dr. Wu Yaohua said, "Innovation comes from demand, and the demand of Vipshop is very representative, and the implementation of the Hive 4.0 system is to respond to the new challenges posed to warehouse logistics by the rapid development of e-commerce in the new environment." As a user, Vice President Tang Yizhi gave this comment: "Vipshop pursues simple, practical, efficient workflow and economical and reasonable cost of use, and BlueSword's Honeycomb E-Commerce 4.0 system matches Vipshop's development concept and continuous optimization of warehouse logistics." So, what are the special characteristics of e-commerce logistics? And what are the shortcomings of traditional solutions?

Dr. Liu Peng analysis, the current rapid development of e-commerce has entered the 4.0 era, a large number of orders, a large number of SKU, order line small, high order timeliness and volatility and other characteristics make it increasingly difficult to deal with, order picking has become a logistics bottleneck that restricts the development of e-commerce, directly affecting customer satisfaction with business services. How to achieve efficient and accurate order picking and rapid response is the key issue facing the development of e-commerce warehouse logistics. For this reason, Lan Jian conducted an in-depth research and analysis on the existing logistics solutions of domestic and foreign e-commerce enterprises.

First, the business characteristics of e-commerce distribution centers are mainly picking and storage, and the difficulty lies in efficient and accurate picking of large scale.

Secondly, e-commerce distribution centers currently mainly adopt the "man-to-goods" zoning combination picking method, in which operators traverse the warehouse to visit the relevant cargo space in a certain area for cargo picking and order consolidation. This method of operation has a large footprint, low picking efficiency, and a large number of personnel. Some e-commerce distribution centers also use semi-automated systems to assist picking with the help of electronic tags, PDAs, conveyors, etc., and use automatic sorting machines for distribution. The use of semi-automated logistics equipment helps to improve the efficiency and accuracy of order sorting, but with the rising labor costs and the continued growth of warehouse rentals, the problem of high distribution center operating costs has not been fundamentally solved.

There have been other attempts in the industry to address the above issues. For example, the centralized automated logistics system, using stacker cranes and conveying equipment to achieve centralized continuous processing of goods, this model is more dependent on a single device, suitable for warehousing-based, picking supplemented by the warehouse. In addition, there is also the practice of "goods-to-person" picking with the help of AGVs, which can reduce part of the operating costs by changing from the traditional centralized to distributed type. However, due to the limited height of the shelves transported by AGVs, the upper space of the warehouse cannot be fully utilized, and the storage cost is still high; moreover, the high cost investment brought by the huge number of AGVs is also difficult to realize the mass application.

How does BlueSword do it?

BlueSword's honeycomb e-commerce 4.0 system superimposes a flat "goods-to-person" system in vertical space, forming a multi-layer 3D "goods-to-person" system with sub-systems and multiple types of intelligent movement units operating in parallel. Dr. Peng Liu explained that the success of the system relies on two foundations: hardware, i.e., advanced intelligent equipment; and software, i.e., the large-scale scheduling algorithm that drives intelligent equipment.

(1) Advanced intelligent equipment

The Honeycomb E-Commerce 4.0 system adopts the fourth generation of BlueSword intelligent lane shuttle, ultra-high-speed transfer shuttle and high-speed vertical hoist. The three types of intelligent movement units are flexible and seamless, and operate stably at high speed to achieve accurate access to goods. At the same time, BlueSword has optimized the design of the intelligent picking station based on ergonomic principles, making the picking operation with shorter identification time, lower movement frequency, smaller movement amplitude, and larger order processing volume in a single batch, and compatible with both B2B and B2C business.

(2) Large-scale scheduling algorithm

To efficiently schedule hundreds of intelligent motion units also depends on two bases: first, to realize the collaboration of multiple intelligent motion units to avoid operational conflicts and disorder; second, to realize real-time dynamic scheduling optimization as orders are sorted or equipment moves. Accordingly, BlueSword Technology Research Institute has researched two core algorithms in a targeted manner. In addition, BlueSword also uses its own core technology - 3D logistics simulation system for support, which can be used both for offline simulation verification of design solutions and as a real-time online monitoring platform for equipment when the system is in formal operation, helping users to monitor the real-time operation status of equipment. According to the reporter's understanding, BlueSword is a domestic logistics system integrator that designs and develops such simulation system and can run offline and online.

Why can BlueSword do it?

Since its establishment in 1993, BlueSword has been devoted to the research of logistics informationization. In 1997, BlueSword started to enter the field of logistics automation and has accumulated rich experience and strong strength in tobacco, medicine, electric power, tire and other industries one after another. When talking about the R&D strength of BlueSword, Vice President Tang Yizhi pointed out, "BlueSword team has invested a lot of time, energy and cost into the R&D of advanced systems, and its R&D achievements have been at the forefront of the international community!"

The professional and technical advantages of BlueSword cannot be separated from the influence of Dr. Wu Yaohua, the founder of the company. He leads a team of PhDs who specialize in their fields of expertise, and it is difficult for such a team not to be strong and professional. Every year, BlueSword's executives and senior technical workers go abroad for further training and implement specific projects, which enables BlueSword to keep pace with the latest foreign logistics technology and applications.

With the technical advantages and high level of professional talents, BlueSword has successfully developed domestic semi-automatic cigarette sorting line, dense piece tobacco storage and distribution warehouse, gravity type tire storage and distribution warehouse, waterfall type automatic drug picker, 3D logistics offline/online simulation system, etc., and formed BlueSword's own rapid sorting theory based on parallel sorting, pre-sorting cache, vector consistency and theories based on dense storage, storage and distribution, SKU unitization, etc. The original logistics theory system based on parallel sorting, pre-sorting cache, vector consistency, and active storage theory based on dense storage, integral storage and SKU monolithic, highlights its strong technical strength.

At the same time, BlueSword also has a self-built logistics equipment science and technology innovation industrial park, in which the assembly and manufacturing workshop has a perfect quality management system and strict production internal control standards, and is responsible for the processing, manufacturing and assembly of BlueSword's intelligent logistics equipment; and the BlueSword Research Institute has been established as an incubation base for BlueSword's new technologies, new products and new achievements, and is responsible for developing intelligent logistics equipment with independent intellectual property rights, large-scale scheduling algorithms, logistics management software and logistics management software. At the same time, the test center of the research institute has a floor area of 4,000 square meters, where the functions and technical performance of all innovative products are subject to strict and comprehensive tests and trials before they are launched. Based on the strong R&D strength and hardware and software level, this modern logistics industrial park will consolidate BlueSword's technological leadership in the logistics field and break through and expand the modern logistics market.

What else can BlueSword do?

Despite the above achievements, the development concept of "only innovation" has been driving BlueSword to keep seeking progress and transcendence. In addition to solving the needs of the e-commerce industry, the Honeycomb system can also provide different solutions to meet the specific needs of various industries to meet different application scenarios of customers, such as forward and reverse logistics in the footwear industry, box picking operations in the daily chemical industry, intensive stock preparation in the cigarette logistics center of the tobacco industry, mass picking and unpicking in the logistics center of the pharmaceutical industry, picking and unpicking in the spare parts warehouse of the manufacturing industry, etc.

"Dr. Wu Yaohua, as the leader of the company, firmly believes that the only way to win a broader space for the survival and development of BlueSword is to continuously innovate and develop advanced systems and technologies. The only way to win a broader space for the survival and development of BlueSword is to continuously innovate and develop advanced systems and technologies, so that it can be compared with the international advanced level and stand on the international market. In the future, people of BlueSword will continue to insist on doing things in a down-to-earth manner and innovate meaningfully to achieve steady development as well as sustainable transcendence!

Fill out your information, BlueSword will provide you professional service!