Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

May 26 /2022

share to

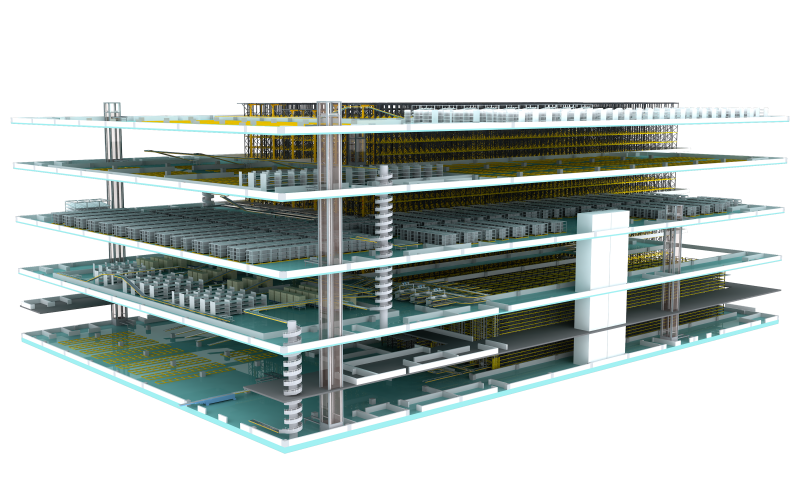

The five-layer structure of the medical device circulation industry platform-type smart warehouse,

How smart and advanced is it?

Platform-type smart warehouse of a large medical group in China (rendering picture)

In view of the characteristics of many SKUs in the medical device circulation business, as well as customer requirements to design to meet the warehousing operation management and operation requirements of 100,000 SKUs, and to have high timeliness requirements for order task response, BlueSword designed and implemented AS/ RS, multi-pass box-type dense warehouse, etc., make full use of the height space of the vertical warehouse to meet the storage needs of massive SKUs. Moreover, the integrated application of multi-pass + traditional AS/RS system realizes the advanced, flexible, flexible and efficient vertical library, which can make traditional AS/RS play a greater role.

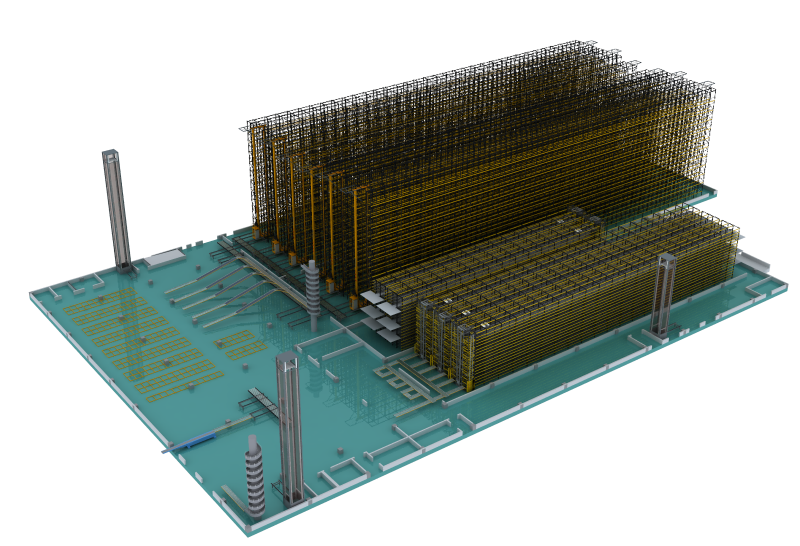

24m automatic high-level pallet warehouse

The AS/RS automated three-dimensional warehouse area is a single-story structure. The total height of the warehouse area is 24 meters. There are more than 15,000 pallet spaces, which can meet the storage needs of 100,000 SKU product types. The AS/RS automated three-dimensional warehouse is the whole pallet storage, adopts the pallet stacker system, and is fully controlled by the computer.

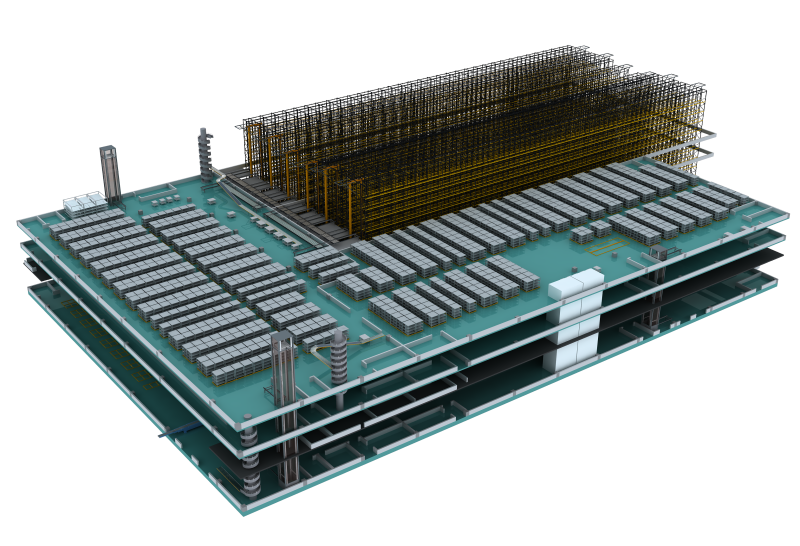

11m automatic multi-wear cold storage & cool storage

The multi-passage warehouse is a two-story structure with a floor height of 11 meters. With the help of the turnover box, the storage of the equipment in the full-scale material box is realized. Multiple multi-carriage systems are used, which are fully controlled by the computer, and cooperate with the goods-to-person picking table, the box changing table and the review packaging table to realize the demolition picking, review packaging and replenishment. cargo work.

Among them, the cold storage area is precisely the application of advanced technologies of multi-pass, intensive storage and distribution and goods-to-person, which can realize high-density storage, goods-to-person picking and efficient automated operations.

Compared with the traditional cold storage operation mode, the application of the cross-temperature zone picking technology in the cold storage not only greatly improves the automation of the storage and sorting operation, but also greatly improves the working environment and labor intensity of the picking personnel. At the same time, since there is no need for picking personnel and forklifts and other vehicles to enter the warehouse, the number of opening and closing of the entrance and exit of the cold storage is greatly reduced, the energy consumption of the cold storage is greatly reduced, and the concept of green and environmental protection is taken into account.

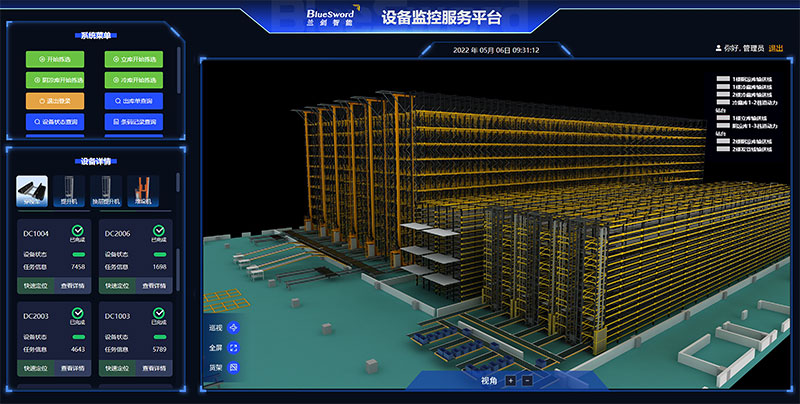

Large-scale application of advanced technology

In this project, the advanced technology concepts of the logistics industry are applied on a large scale. For example, the new technology of core-picking integration is adopted for dismantling and picking. On the basis of the goods-to-person picking workstation, automation and information equipment such as lighting, screen display and code scanning are used combined with intelligent equipment. The software monitoring system can realize the review operation while picking. The pallet-level flexible handling technology is partially applied in the warehouse to realize unmanned operation, high efficiency, intelligence and sustainable operation in the corresponding area (unmanned operation can be performed 24 hours a day).

In addition, a number of mature and advanced logistics equipment technologies are integrated, such as automatic online labeling technology, online multi-faceted code reading technology for boxes, automatic cargo shape detection technology, automatic detection technology for deformation and damage of vertical warehouse pallets, telescopic chain plate machine + Robotic automatic palletizing technology, automatic vehicle loading and unloading technology in the warehouse, combined demolition and palletizing technology based on machine vision (3D vision technology) + robotic arm, and BlueSword digital twin system have been fully applied.

Empowering leading customers to shoulder social responsibility

After the completion of the project, both the storage capacity and the efficiency of picking operations in the warehouse will be greatly improved compared to the traditional model. Under the same area, the storage capacity will be increased by 4-5 times. , which can realize warehouse management operations of 100,000 level and above.

The "goods-to-person" picking form has greatly improved the efficiency of personnel operations; and the previous form of personnel-intensive warehousing operations has been upgraded to a highly automated and information-based smart unmanned warehouse, which reduces personnel input costs and greatly reduces customer costs. The logistics operation cost has greatly improved the core competitiveness of the customer market. At the same time, it has a safe and efficient order response capability, which shortens the order response capability of part of the business coverage to 30-60 minutes, which is a qualitative improvement compared to the traditional form of order response capability in "days".

The increase in reserves and efficiency enables customers to have stronger supply chain service capabilities for prevention and control materials, as well as the ability to efficiently allocate emergency materials. Moreover, the improvement and implementation of the SPD off-hospital warehouse solution in the smart warehouse will effectively improve the supply and management capabilities of medical supplies such as hospital consumables, thereby enhancing the hospital's medical service capabilities.

In the future, BlueSword will give full play to its own logistics technology and service advantages to provide customers in the medical device industry with more advanced, highly automated, information-intelligent, safe and efficient medical device storage and selection innovative solutions.Promote the value upgrade and high-quality development of the medical device supply chain, and contribute wisdom to epidemic prevention and control and the construction of the national public health system!

Fill out your information, BlueSword will provide you professional service!